Robotics Compliance 101

Understanding the Path to Safe, Scalable, and Trusted Robot Deployment

As robotics continues to expand from factories into hospitals, warehouses, farms, and construction sites, ensuring safe operation in these human-centric environments is no longer optional—it's essential. Robots must be effective, but they must also be provably safe, reliable, and compliant with regional regulations.

This post walks through the basics of robotics compliance, what makes it unique, and how teams can navigate the process to bring certified, trustworthy systems to market.

Why Is Robotics Compliance Different?

Unlike static hardware, robots are dynamic systems. They move, sense, make decisions, and interact with people and the environment in real time. That complexity introduces more points of failure and a higher bar for safety validation.

Key challenges that set robotics apart:

- Motion safety: Preventing unintended movement, collisions, or unsafe speeds.

- Software safety: Ensuring software decisions do not create hazards—even in edge cases.

- Environmental unpredictability: Adapting to cluttered, changing, and human-dense settings.

- System integration: Many robots combine mechanical, electrical, and embedded software systems, each with their own compliance requirements.

What Compliance Covers for Robotics

Robotics compliance spans multiple categories:

- Functional Safety: Ensuring the system continues to operate safely even when faults occur. Standards like ISO 13849, IEC 62061, and IEC 61508 apply.

- Electrical Safety: Minimizing risks from batteries, power supplies, and high-voltage components. UL 3100 and IEC 61010 are common standards.

- EMC/EMI: Making sure the robot doesn’t interfere with—or get affected by—other electronics.

- Software Assurance: For robots making safety-critical decisions, software reliability becomes a formal requirement.

- Human-Robot Interaction (HRI): Ensuring the robot can detect, avoid, or safely work alongside humans using LIDAR, bumpers, emergency stops, or collaborative modes.

Core Standards and Bodies for Robotics

| Domain | Example Standards | Key Bodies |

|---|---|---|

| Robot Arm Safety | ANSI/RIA R15.06 / ISO 10218-1 | RIA, ISO |

| Mobile Robot Safety | ANSI/RIA R15.08 / ISO 3691-4 | RIA, ISO |

| Functional Safety | ISO 13849, IEC 61508 | IEC, ISO |

| Electrical Safety | UL 3100, IEC 61010 | UL, IEC |

| Cybersecurity | ISO 21434, IEC 62443 | ISO, IEC |

| AI Software | UL 4600, ISO/IEC 23894 | UL, ISO |

Depending on where your product is sold, you may also need to follow CE, UKCA, or NRTL markings—and work with labs like UL, Intertek, or TÜV SÜD to certify your product.

The Compliance Process: End-to-End

-

Define the Product and Use Cases

- Is it a collaborative arm, an AMR, or a teleoperated robot?

- Is it used in factories, warehouses, public spaces, or construction?

-

Identify Markets and Regulations

- Which regions will you launch in: US, EU, CA, JP, etc.?

- Will third-party certification be required?

-

Determine Applicable Standards

- Functional safety, electrical, mechanical, EMC, and HRI standards

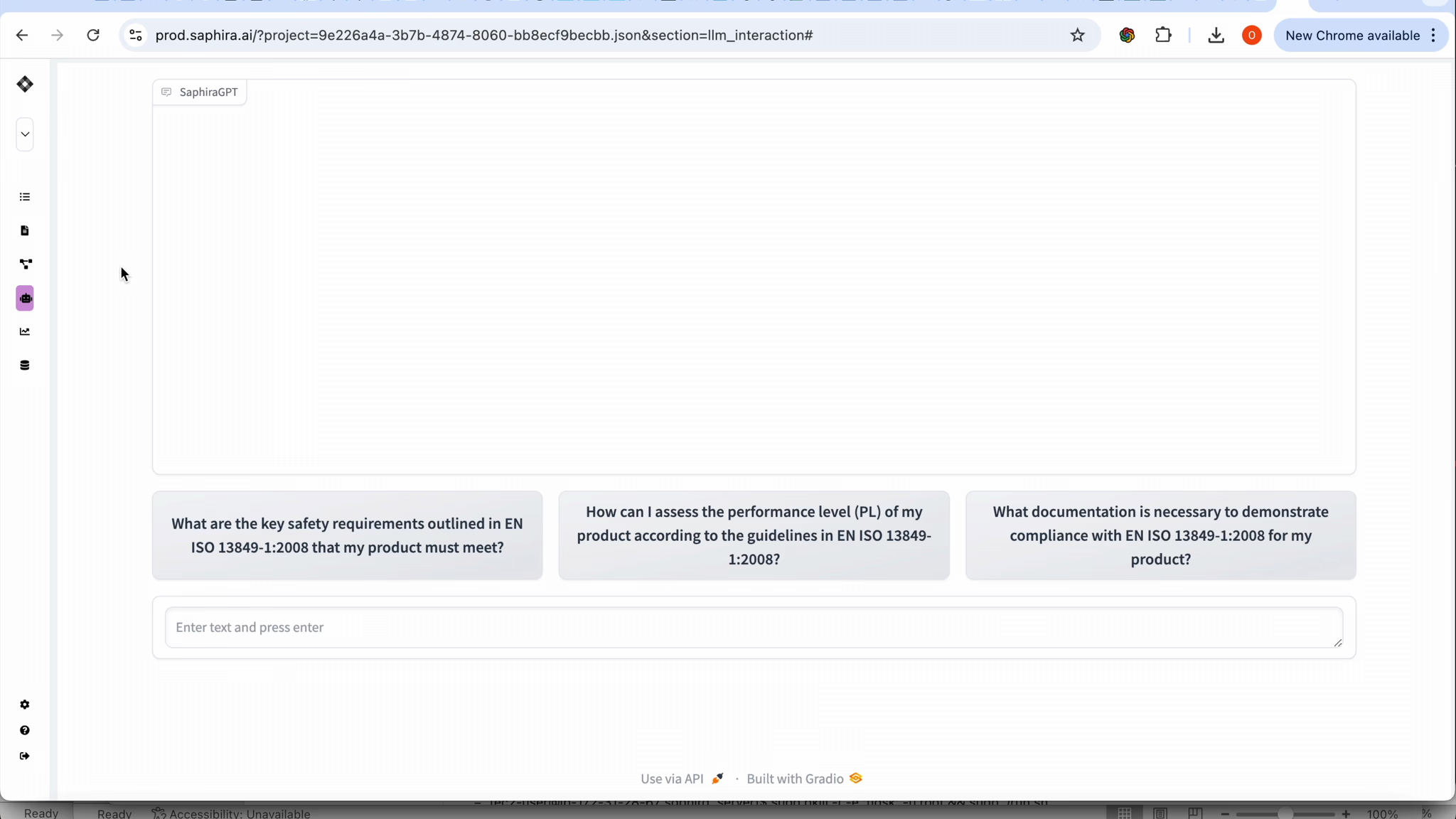

- Saphira can help identify these based on your responses

-

Design for Compliance

- Use certified components where possible

- Build in safety-rated motion control, emergency stops, and protective features

-

Validate and Test

- Risk assessments (FMEA, HARA)

- Simulated and real-world fault injection

- Third-party or internal testing per standards

-

Document Everything

- Risk files, design specs, software assurance cases

- Version-controlled documentation that can withstand audits

-

Certify and Maintain

- Submit to a lab (UL, Intertek, TÜV) or self-declare

- Maintain post-market traceability and support updates

Common Pitfalls to Avoid

- Waiting until the end: Safety can't be bolted on—it must be built in from the start.

- Assuming one standard fits all: Different markets and robot types have different requirements.

- Undervaluing documentation: Poor or missing documentation is one of the most common causes of audit failure.

- Skipping software validation: Especially for robots with autonomous or semi-autonomous capabilities, rigorous testing and assurance are critical.

How Saphira Helps

At Saphira, we simplify the robotics compliance journey:

- Automatically identify relevant standards by robot type and geography

- Generate safety analyses and validation reports

- Track documentation across versions and releases

- Prepare your team for audits and certifications from day one

Final Takeaway

If you’re building or deploying robots, compliance isn’t just a checklist—it’s a critical enabler of safety, scale, and trust. The earlier you build it into your process, the faster and smoother your path to market becomes.

Ready to make compliance a growth advantage?

Book a demo with Saphira to get your robotics platform audit-ready.