The world of control panels and enclosures is not only a bit more complex than most realize but it is also very tightly regulated. One of the standards followed in industry is UL 508A, which is a safety standard for industrial control panels in the United States.. The first edition was published in 2001. Starting from the basics of electrical safety, stated by the NEC and looking at the prescriptions stated in NFPA 79, it gives indications for the design of industrial control panels.

It defines how to build and label panels to reduce fire and electrical hazards. Control panel builders, electrical engineers, and inspectors use it as a baseline when designing and evaluating panels for general industrial use. The standard applies to panels operating at 1000 volts or less. The previous version of this standard only allowed 600V max. The standard is divided into two parts:

PART 1 – GENERAL USE INDUSTRIAL CONTROL PANELS..

PART 2 – SPECIFIC USE INDUSTRIAL CONTROL PANEL TYPES

Part 1 applies to all control panels in part 2. It is the manufacturer’s responsibilty to choose the right sub sectrion of part 2 which includes control panel desgin requirement for air condition, fountain control, water park rides, etc.

Scope of UL 508A

UL 508A applies to industrial control panels operating at 1000 volts or less, intended for general industrial use in ordinary (non-hazardous) locations. It includes panels used in applications like:

- Machinery control (e.g. CNCs, presses, injection molding machines)

- HVAC, irrigation, cranes, hoists, and fountains

- Marine, elevators, fuel-burning equipment

- Water parks, pools, and spas

- Load management and energy systems

- The standard covers assemblies of control components like motor controllers, relays, pushbuttons installed within or on enclosures or sub-panels.

UL 508A does NOT cover:

- The equipment being controlled (e.g. motors, heaters)

- Remote devices not mounted in or wired to the panel

- Building structures or platforms housing panels

- Panels for hazardous locations (covered under UL 1203 or UL 698A)

- Fire alarms, emergency systems, fuel cells, communication panels, and access control systems—these fall under other specific UL standards

Simply put, UL 508A focuses on the control panel itself—not the field devices, remote systems, or special-use categories that are governed by other standards

Elements of UL 508A

UL 508A sets minimum requirements for the construction of industrial control panels. It covers:

- Selection of components

- Calculation and labeling of short circuit current ratings

- Overcurrent protection

- Wiring methods

- Spacing and layout

- Grounding and bonding

- Enclosure ratings

- Marking and documentation

The standard applies to a wide range of equipment, including motor control centers, machinery control panels, and automation panels.

UL 508A Panel Shops

A UL 508A panel shop holds a certification from UL or any other NRTL(Nationally recognized testing laboratory) like Intertek, CSA, Nemko, to apply the UL label to panels it manufactures. The shop follows a procedure that NRTL audits regularly. This procedure includes documentation, quality control, and recordkeeping.

Certification allows the panel shop to build multiple panels under the same compliance process without submitting each one to individual evaluation.

Component Requirements

UL 508A requires all components in the panel to meet UL standards. Appendix A of UL 508A mentions most of the components and the applicable standard for those components. The builder selects components that are listed, recognized, or classified(see below section for definition) for their intended use. The panel design must reflect the ratings and installation instructions of these components. This includes circuit breakers, contactors, terminal blocks, power supplies, relays, and more. Builders must consider factors like temperature ratings, spacing, and mounting when installing components.

UL Listed vs Recognized vs Classified.

This is a confusing part for most builders new to certification.

UL Listed: This is a component assessed by a certification body as per the applicable standard for all possible use cases and environment. No further evaluation of the component after installation in the final system is needed. So basically a ready to use component is called UL Listed.

UL Recognized: This is a component which is assessed just like UL Listed, but there are some conditions of use, also called “conditions of acceptability”. These conditions must be met in the end use product or system and then, the end product is evaluated as per applicable standard.

UL Classified: These are components assessed just like UL listed, but only for certain properties, conditions or hazards and not for full general use case.

Spacings

Spacing is a critical safety consideration in industrial control panels, with specific requirements outlined in UL 508A to prevent electrical arcing and ensure insulation between live parts. These requirements vary based on voltage levels and the type of circuit.

For instance, spacings in branch and control circuits are specified in Table 10.1 and Table 10.1A, while spacings for feeder circuits are found in Table 10.2. The standard addresses spacing between uninsulated live parts of adjacent components, between live parts and grounded or accessible dead-metal parts, between live parts and the enclosure, and at field wiring terminals. Adherence to these spacing requirements is essential for the safety and reliability of industrial control panels.

Short Circuit Current Rating (SCCR)

The panel's SCCR indicates the highest level of fault current the panel can withstand safely. UL 508A outlines how to calculate and label this value.

Panel builders determine the SCCR based on the lowest-rated component in the power circuit. They can increase the SCCR by using current-limiting devices or components with higher interrupting capacity.

The standard requires builders to mark the SCCR on the panel nameplate. Inspectors and end-users rely on this rating to verify compatibility with the available fault current at the installation site.

Overcurrent Protection and Wiring

UL 508A includes requirements for protecting circuits against overcurrent. Builders select fuses or circuit breakers with the correct interrupting capacity and coordinate protection with downstream devices.

The standard also defines acceptable wiring methods, including conductor types, routing, and sizing. It sets spacing requirements between live parts and grounded metal, and between different voltage levels. These clearances help prevent unintentional contact or electrical arcing.

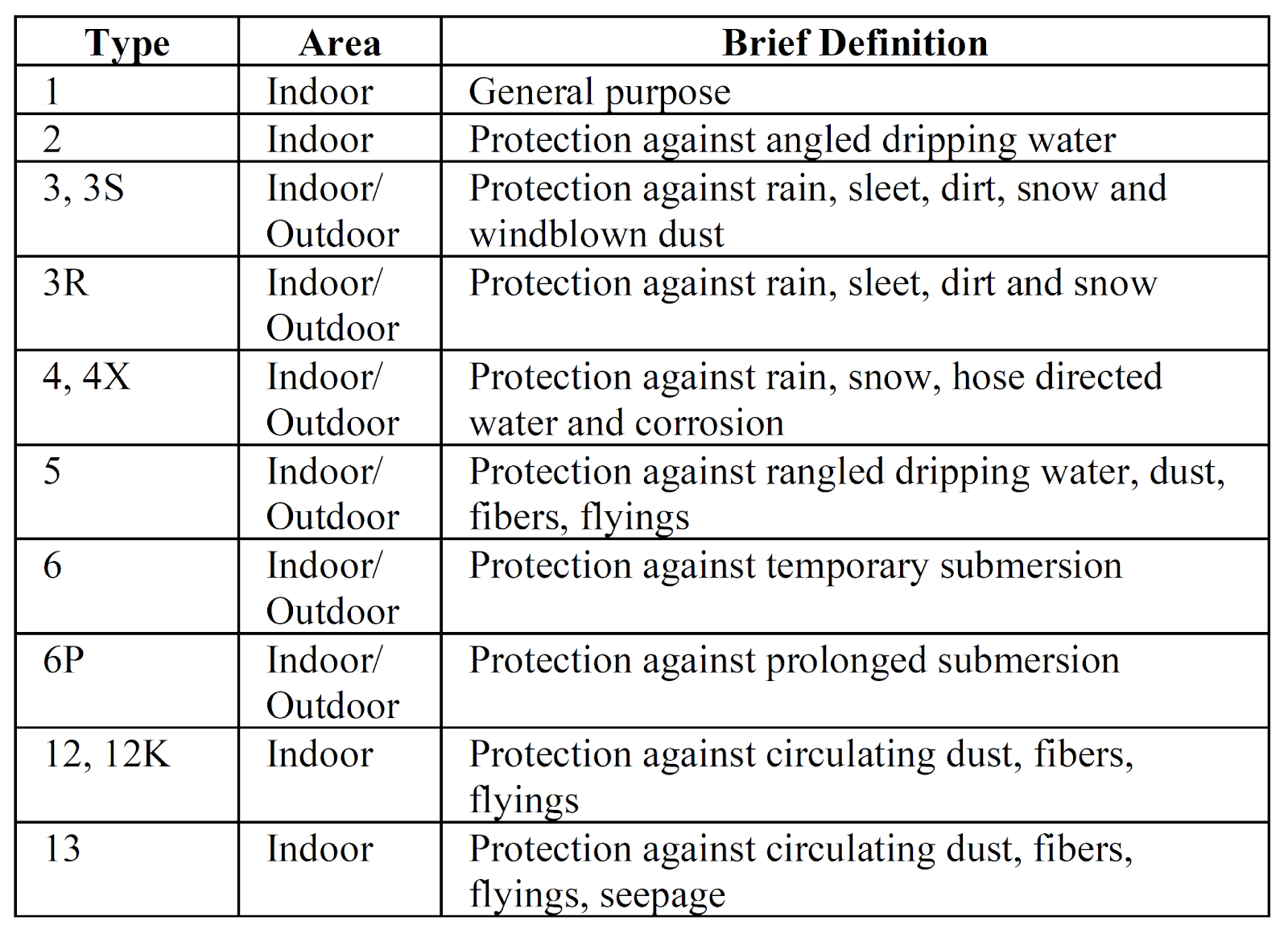

Enclosure

The enclosure must meet the requirements of UL 50, UL50E, or clause 62 to 64 of UL508A. This is important to prevent short circuit and fires. If a control panel is to be installed in an environment where it is exposed to dust, snow, rain, the applicable enclosure certified to type should be used. If a custom enclosure is needed, the enclosure including all openings, cable glands, conduit fittings, etc. must be assessed to the requirements of all standards and clauses applicable.

Marking and Documentation

Each UL 508A panel must include a label with specific information. The label lists the panel's electrical ratings, SCCR, and the UL file number of the manufacturer.

The panel shop maintains documentation for every labeled panel. This includes a bill of materials, layout drawings, wiring diagrams, and calculation sheets. UL reviews these documents during regular audits.

Summary

UL 508A establishes a consistent framework for the design and construction of industrial control panels. It defines how to select components, build safe assemblies, and communicate key information to inspectors and users.

Builders who follow UL 508A reduce the risk of electrical hazards and support consistent evaluation by authorities having jurisdiction.

If you’re looking for help complying with UL 508A or any related standards, reach out to us at contact@saphira.ai or book a call!